Today, Orca Semiconductor announced the OS2000, an advanced IO-Link communications transceiver engineered for industrial settings. Orca launched its first product, the OS1000 back in June . As the company's second product release, this new transceiver continues the company's focus on application-specific analog solutions. The OS2000 promises significant improvements in device performance, integration, and flexibility.

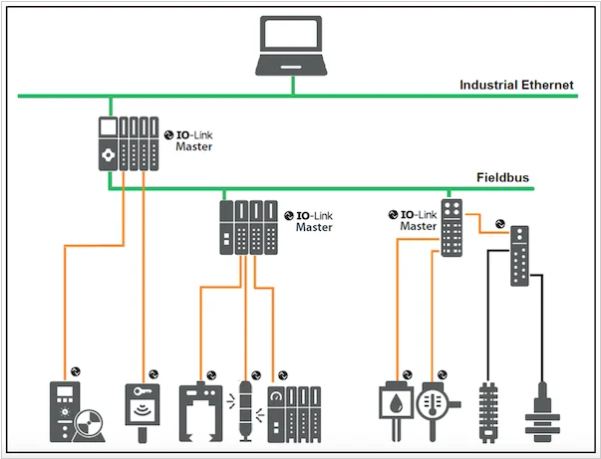

Example of a system architecture with IO-Link. Image used courtesy of IO-Link

A New Standard in Device Integration and Adaptability

The industrial sector has seen a steady rise in IO-Link transceivers as manufacturers increasingly rely on factory intelligence.

“Orca was founded to bring application-specific analog innovations in a nimble and accessible way for customers who have been neglected by ‘Big Analog’ players,” Baker said. “We aim to be faster than the Big Analog players, outpacing both in execution and, eventually, innovations we bring to the market."

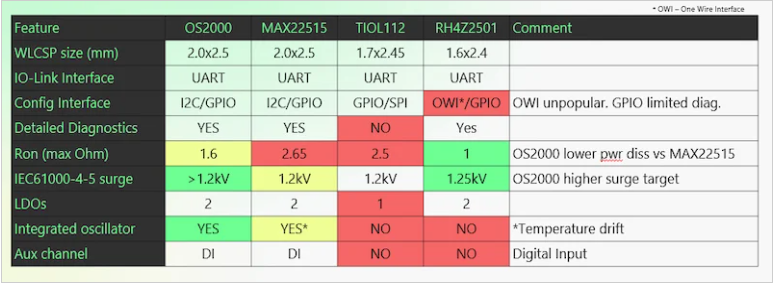

While leading competitors like Texas Instruments and Renesas offer IO-Link transceivers, Orca Semi’s OS2000 IO-Link transceiver distinguishes itself with high integration and design flexibility, both hallmarks of the device’s architecture.

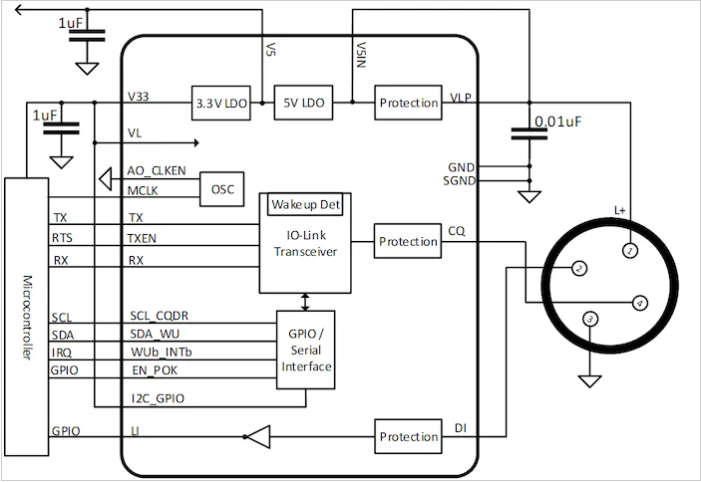

OS2000 block diagram and application circuit. Image used courtesy of Orca Semiconductor

Built to accommodate challenging industrial environments, the OS2000’s 2.5 mm x 2.0 mm WL-CSP-20 package integrates two linear voltage regulators, a digital input channel, an onboard clock generator, and surge protection. These features collectively minimize the need for external components, allowing the OS2000 to fit within space-constrained applications while maintaining a stable 24-V power input range across 8 V to 36 V.

Unlike competing devices that require additional external components to manage power and interface controls, the OS2000’s built-in voltage regulators (3.3 V and 5 V), I2C-controlled driver current settings, and an optional clock output for timing compliance contribute to its compact form factor and simple installation.

Further, the OS2000’s capacity to serve both IO-Link master and device configurations enhances its adaptability to varying industrial setups. Compared to Analog Devices' popular MAX22515, which Orca aims to replace in many applications, the OS2000 reportedly offers a more integrated architecture, reduced footprint, and decreased power dissipation requirements.

Enhanced Performance for Industry 4.0

The company attributes many of the device’s strengths to Orca’s partnership with a foundry specializing in deep trench isolation (DTI) technology, which improves resistance to electrical interference and reliable operation in harsh environments with heavy noise from motors and actuators.

“DTI is really about the isolation of the substrate so you don't get an injection of electrical interference through parasitic devices within the design,” Baker said. “This will help us not just now but also in the future in terms of the rapid integration of additional features at a lower risk versus non-DTI technologies.”

Beyond the DTI technology, the OS2000 can maintain robust signal integrity due to its surge protection measures. These measures guard the power, communication, and input channels from reverse polarity and voltage surges up to ±1.2 kV at 500 Ω. In addition to this protection, its auxiliary digital input allows manufacturers to expand the transceiver’s functionality without additional circuitry. Furthermore, the device supports communication rates spanning COM1, COM2, and COM3 ranges, suiting high and low data rate applications across industrial IoT (IIoT) setups.

OS2000 competitive analysis. Image used courtesy of Orca Semiconductor

In terms of specifications, the device’s driver current can be set at 50 mA, 100 mA, 200 mA, or 250 mA. Through the I2C control interface, users can adjust the driver’s slew rate with fine-tuned control over signal characteristics. This level of control also minimizes unnecessary power consumption. Orca’s internal oscillator design is another notable addition, offering five output frequencies and allowing the device to serve as a system clock for microcontrollers.

The OS2000 also aligns with Industry 4.0 standards, specifically through compliance with IEC61131-9. This standard defines IO-Link sensor and actuator communication protocols. Orca designed the transceiver to facilitate point-to-point communication with minimal latency. By using IO-Link’s single-drop digital communication interface (SDCI) for small sensors and actuators, the OS2000 allows industrial setups to access real-time performance data.

Positioning and Timeline

Orca’s release of the OS2000 highlights the company’s operational growth and ambitions within the industry.

“This is the first step in our big ambition of more integration,” Baker said. “The next step in our vision is to have more proprietary types of products, and this is a launching pad in that direction.”

General sampling is expected in Q2 2025, with mass production slated for late 2025.

All images used courtesy of Orca Semiconductor.

English

English