STMicroelectronics recently introduced a new extensible memory solution , xMemory, into its Stellar series of automotive microcontrollers. Underpinned by a number of unique technological advances, xMemory gives Stellar MCUs scalable, in-field memory expansion to support dynamic automotive software demands without a hardware redesign.

ST claims PCM provides significantly higher memory density than flash-based embedded NVM.

ST Introduces xMemory Based on ePCM

xMemory is a new memory solution based on ST’s proprietary embedded Phase Change Memory (ePCM).

This non-volatile memory technology, developed on ST’s 18-nm and 28-nm FD-SOI process nodes, features the so-called industry’s smallest bit cell geometry to achieve higher density and lower power than traditional flash. By embedding PCM directly into the MCU architecture, xMemory enables fine-grained control over memory allocation and provides deterministic access times for real-time automotive functions.

Compared to external memory or discrete flash solutions, xMemory allows users to dynamically configure memory size across a range of capacities, starting at baseline configurations like 10 MB and scaling upward without requiring hardware changes.

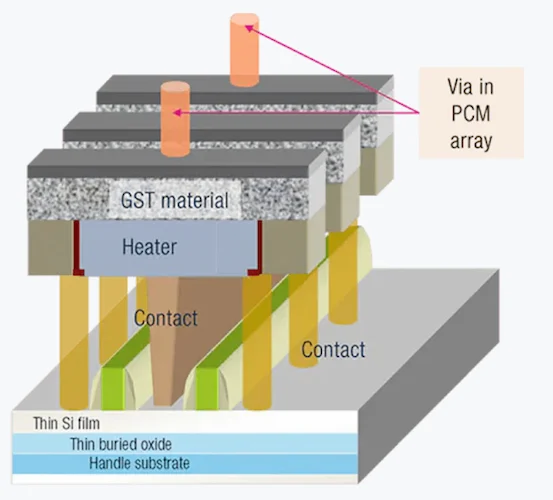

ST's PCM technology architecture.

PCM extensibility relies on a hardware-software co-design that combines physical overprovisioning of memory cells, secure activation mechanisms, and dynamic memory mapping. During fabrication, ST provisions more PCM than is initially exposed to the system. This latent capacity is gated by fuse-based controls or secure configuration registers, which developers can trigger through authenticated firmware or over-the-air updates to unlock additional memory blocks.

The MCU’s memory controller then supports dynamic remapping. Once new regions are activated, firmware updates the memory map without modifying the underlying hardware architecture. In this way, the Stellar xMemory platform decouples memory planning from hardware design, allowing memory extensibility during development or post-deployment through over-the-air updates. This conceptual shift responds to the long-standing tradeoff in automotive design where overspecifying memory increases bill-of-material costs, while underspecifying introduces redesign risk.

A Primer on Phase-Change Memory

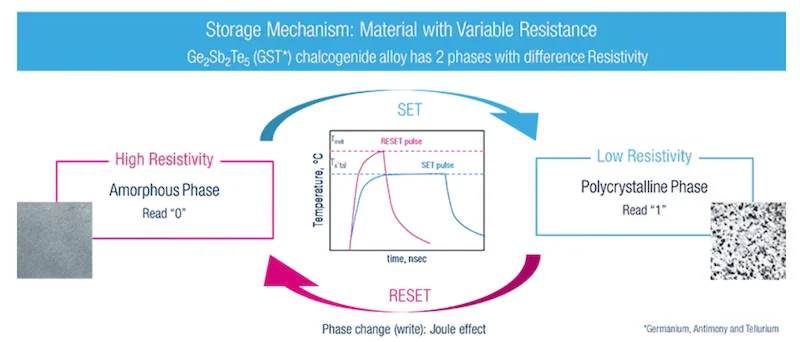

Phase-change memory is a non-volatile memory (NVM) technology that uses the reversible transformation between amorphous and crystalline states of a chalcogenide alloy to store binary data. While floating gate transistors are used in flash memory, PCM cells switch between high-resistance (amorphous, logic 0) and low-resistance (crystalline, logic 1) states through localized heating generated by electrical pulses. This heat-induced phase transition alters the material’s atomic structure without requiring charge storage for precise and repeatable write and erase operations.

The storage mechanism of PCM.

STMicroelectronics implements PCM using a fully depleted silicon-on-insulator (FD-SOI) process at 18-nm and 28-nm nodes. ST claims that this integration delivers high-density, on-die NVM with a significantly smaller footprint than traditional flash-based embedded NVMs. ST's architecture includes a heater beneath each memory cell to induce rapid phase transitions with low voltage and low current, allowing write speeds in the microsecond range and read latencies comparable to SRAM-class memory.

A major advantage of PCM is its ability to combine DRAM-like performance with flash-like persistence, without the endurance limitations or data retention degradation seen in other NVM technologies. Meanwhile, the scalability of PCM enables memory granularity on the order of megabytes per block.

xMemory to Make Its Debut in Stellar P6 MCUs

With memory becoming a design bottleneck in software-defined vehicles, PCM is an exciting new solution toward deterministic, low-latency memory expansion. The first xMemory-equipped devices will be released on the Stellar P6 MCU series, targeting EV powertrain control in late 2025.

English

English