Modern vehicles use networked electronic systems to keep drivers safe in conditions where mechanical grip is limited. Vehicle Stability Control (VSC) Toyota’s implementation of Electronic Stability Control (ESC) continuously compares the driver’s steering intent with the vehicle’s actual motion. When sensors detect understeer, oversteer, or wheel-slip, the control unit applies brake pressure to individual wheels and reduces engine torque to help the car follow the intended path.

When the VSC light appears on your dashboard, it means the stability system is actively intervening, has been turned off, or has detected a fault. For engineers, technicians, and procurement professionals, understanding how VSC works and why the VSC light Toyota models display is essential for accurate diagnosis, parts selection, and safe operation.

Toyota dashboard with VSC light illuminated in amber.

What the VSC Light Is Telling You

- Flashing VSC light: VSC is currently correcting a loss of stability (normal intervention).

- Solid VSC light: Fault detected; the stability system may be partially or fully disabled.

- VSC OFF light: The driver manually disabled VSC (often paired with TRAC OFF).

- VSC Check Engine: Engine or drivetrain fault is affecting torque management; stability features may be limited.

- VSC ABS light: Shared sensor/module issue (e.g., wheel-speed sensor, ABS ring, wiring).

Comparison of Toyota dashboard indicators for VSC, VSC OFF, and TRAC OFF.

How VSC Works (Engineering View)

VSC is a closed-loop stability controller that uses sensor fusion and brake/engine actuators:

Primary Sensors

- Wheel-speed sensors (ABS rings): Measure individual wheel rotation; foundational for slip detection.

- Steering-angle sensor: Reports steering wheel position to infer desired yaw rate.

- Yaw-rate sensor: Measures rotational velocity about the vertical axis to quantify over/understeer.

- Lateral-acceleration sensor: Gauges side force to refine slip estimates and stability thresholds.

Control Unit & Actuators

- Brake actuator/modulator: Applies hydraulic pressure to one or more wheels for corrective yaw moments.

- Engine control (via CAN): Commands throttle/ignition/fuel reductions to limit torque during interventions.

- Integration with TRAC & ABS: Traction events (wheel spin) and anti-lock brake events are coordinated to avoid conflicting actions.

Example Interventions

- Understeer (car pushes wide): Brakes the inside rear wheel, sometimes the inside front, to rotate the vehicle toward the intended line.

- Oversteer (rear steps out): Brakes the outside front wheel to counter yaw and stabilize the chassis.

- Low-µ surfaces (snow/rain): Limit torque and meters brake force to maintain longitudinal and lateral grip.

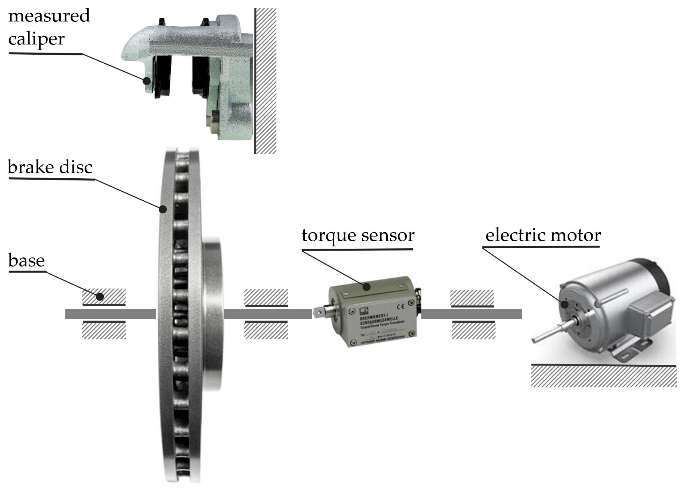

Vehicle Stability Control block diagram showing sensors, ECU, and actuators.

Indicators in Toyota Vehicles

Toyota and Lexus clusters typically use an amber VSC light for status and a separate VSC OFF lamp for driver-disabled mode. During normal driving, short bursts of flashing are common on slippery roads or abrupt maneuvers. A persistent solid light indicates a fault requiring diagnosis. Some models will also illuminate TRAC OFF or the ABS lamp when the fault involves shared components.

Tip for technicians: Note customer reports about road conditions and maneuvers when the lamp appeared; intermittent faults often correlate with rain, snow, or gravel.

Location of the VSC OFF button in a Toyota interior.

Common Causes of VSC Light Illumination

| Cause | Technical Explanation | Driver Symptoms |

|---|---|---|

| Engine Misfire | Misfire disrupts torque → VSC triggered. | Engine vibration, CEL ON, loss of power. |

| ABS Sensor Failure | Wheel speed misread → ECU loses accurate data. | ABS light ON, poor braking control. |

| Steering Angle Sensor Fault | Wrong steering data after alignment. | Steering wheel off-center, stability loss. |

| Yaw Rate Sensor Malfunction | Incorrect angular velocity reading. | Frequent false VSC activations. |

| Low Tire Pressure / Grip Issues | Uneven traction causes VSC overcorrection. | Light appears in wet/icy conditions. |

| ECU / Wiring Fault | Communication errors between modules. | Multiple warning lights at once. |

Damaged ABS wheel-speed sensor wiring is a common VSC fault source.

Is It Safe to Drive with the VSC Light On?

- Dry, straight, low-speed driving: Generally safe short-term, but stability aids may be reduced or disabled.

- Wet/icy, gravel, steep grades, emergency maneuvers: Risk increases; avoid spirited driving and heavy loads.

- Critical case: If VSC flashing Check Engine shaking occur, treat as an engine fault, stop hard use, and diagnose immediately.

Best practice: Advise customers to schedule diagnostics promptly; prolonged faults can mask real traction events and increase stopping distances.

Diagnostic Workflow

- Interview & road test: Reproduce conditions if safe (surface, speed, steering inputs).

- Scan all modules: Powertrain, ABS/VSC, body; record freeze-frame data and monitor wheel speeds live.

- Battery/charging check: Low voltage corrupts reference signals; measure under load.

- Sensor validation: Compare commanded vs measured steering angle; plot yaw vs lateral-G consistency on a gentle slalom.

- Wheel-end inspection: Check tone rings for cracks/packed debris; verify harness strain relief at knuckles.

- Calibrations: Perform zero-point calibration (yaw/G) and steering-angle calibration after alignment or sensor replacement.

- Actuator tests: Command ABS pump/solenoids to verify hydraulic response.

Common Toyota DTCs to note

- C1201: Engine control system fault reported to ABS/VSC (investigate powertrain codes).

- C123X series: Wheel-speed sensor/ring faults (X varies by corner/condition).

- C1336: Zero-point calibration required (yaw/lateral sensors).

- C1432/C1433: Steering-angle sensor out of range/not learned.

Live data view of wheel speeds used for VSC diagnostics.

Repair & Recalibration Guidance

- Misfire/torque faults: Replace plugs/coils/injectors as indicated; verify coil dwell and injector balance; clear fuel-related DTCs.

- Wheel-speed sensors: Replace with quality parts; clean/replace tone rings; route wiring exactly as OEM to avoid rub points.

- Steering-angle sensor: Ensure the steering wheel is mechanically centered; run calibration and verify full-lock symmetry.

- Yaw/lateral sensors: Mount at the specified orientation and torque; perform zero-point calibration on level ground.

- ABS hydraulic unit: Bleed per service procedure; run actuator bleed routines after replacement.

- Grounds & power: Refurbish corroded grounds, verify voltage drop under load, and repair chafed harnesses.

Steering-angle sensor calibration after alignment key to clearing VSC warnings.

How to Temporarily Turn VSC OFF

Certain low-µ scenarios (deep snow, loose sand, stuck recovery) may benefit from reduced stability intervention:

- Press or press-and-hold the VSC OFF (or TRAC OFF) button per model instructions.

- Expect VSC OFF and/or TRAC OFF lamps to illuminate.

- Most Toyotas re-enable VSC automatically after a key-cycle or above a threshold speed.

Caution: Disabling VSC reduces safety margins. Always re-enable for normal road use.

Procurement Notes (For Engineers & Buyers)

When sourcing replacement parts or specifying components for new builds, consider:

- Sensor type & protocol: Confirm connector keying, wire mapping, and signal type (digital hall vs variable reluctance).

- Environmental ratings: Temperature range, sealing (IP67 for wheel-end sensors), and vibration specs.

- Accuracy & drift: SAS absolute accuracy and yaw sensor zero-point drift directly impact false triggers.

- Electromagnetic compatibility: Immunity to ignition noise and high-current loads near ABS harnesses.

- Traceability & QA: Batch tracking, PPAP or equivalent documentation for OEM programs.

- Lifecycle & availability: Align multi-year service obligations with supplier EOL policies; maintain second sources.

- Regulatory & safety: Components should support ISO 26262 workflows where applicable (ASIL decomposition, diagnostics).

Bettlink recommendation: Standardize on vetted sensor families and keep a cross-reference table of equivalent parts by connector, mount, and calibration requirements to simplify field service.

Automotive wheel-speed sensor example of a high-reliability VSC input device.

Troubleshooting Examples

Case A: VSC Check Engine shaking at idle

Scan reveals misfire on cylinder 3 (P0303) and C1201 in ABS/VSC. Replacing the ignition coil and plugs clears both the drivability issue and the VSC lamp after a short drive cycle.

Takeaway: Powertrain faults can cascade into stability warnings because torque control is integral to VSC logic.

Case B: VSC after alignment service

No powertrain codes; ABS shows C1433 steering-angle out of range. Performing SAS calibration and verifying the centered wheel position extinguishes the light.

Takeaway: Always recalibrate SAS after toe/camber adjustments or column work.

Case C: Intermittent VSC in heavy rain

Live data shows wheel-speed dropouts from the right-rear corner; physical inspection finds a cracked tone ring filled with rust. Replacing the ring and sensor fixes the issue.

Takeaway: Moisture and debris at wheel ends are frequent root causes; visual inspection is critical.

FAQ (Engineer & Driver Focused)

Q1. What’s the difference between VSC and TRAC?

VSC handles yaw stability (over/understeer). TRAC limits wheel spin during acceleration. They share sensors and often coordinate actions via the same ECU.

Q2. Why does the VSC light come on with the Check Engine light?

The stability system depends on a predictable engine torque. Misfires or throttle faults reduce torque authority, so VSC posts a warning and may limit assistance.

Q3. Can low battery voltage trigger the VSC light?

Yes. Voltage dips corrupt sensor references and CAN communication. Load-test the battery and alternator before chasing deeper faults.

Q4. Do tire sizes matter for VSC?

Absolutely. Mixed sizes/uneven wear change rolling circumference and confuse wheel-speed correlation, causing premature interventions or fault flags.

Q5. How do I reset the VSC light without a scanner?

If the underlying issue is resolved (e.g., a loose connector reseated), some models clear after several key cycles and a short drive. Persistent lights require code clearing and calibrations via a scan tool.

Q6. Is it okay to drive with VSC OFF?

Only when conditions demand it (deep snow, sand, extraction). Re-enable VSC for normal roads to restore safety margins.

Q7. After replacing a yaw sensor, the light is still on. Why?

Most models require a zero-point calibration on level ground after replacement. Also, confirm correct mounting orientation and torque.

Q8. Can warped brake rotors trigger VSC?

Severe judder can confuse wheel-speed readings during braking. Address mechanical brake issues before deeper electronic diagnostics.

Q9. Does VSC affect fuel economy?

Negligible in normal conditions; interventions are brief and only during instability events.

English

English