Researchers at Ohio State University have developed a smart insole that combines high-resolution pressure sensing, onboard solar power, and machine learning to analyze gait in real time.

Gait analysis can reveal important information about skeletal, nervous, and muscular systems.

Designed to monitor how people walk, run, and stand, the system offers continuous insight into biomechanics, with potential applications across clinical diagnostics, rehabilitation, and personalized health monitoring.

Sensor Architecture and Power System

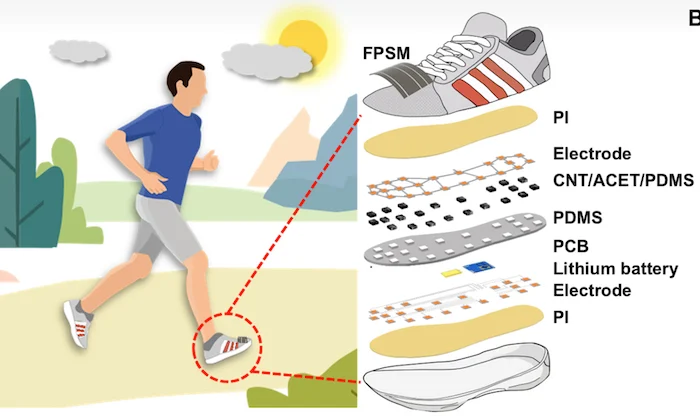

The insole features 22 pressure sensors embedded in a polydimethylsiloxane (PDMS) matrix. These sensors are made from a composite of carbon nanotubes, acetylene black, and PDMS (CNT/ACET/PDMS). The material was engineered using a “nonlinear synergistic” strategy, which cancels out the nonlinear behavior in both the electrical and mechanical response. The result is a linear sensor output across a pressure range of 0 to 225 kPa, with accuracy above 99.9% (R² > 0.999).

Sensor placement is not uniform: eight sensors are located in the toe area, six in the heel, six in the metatarsal region, and two in the arch. This layout reflects the variation in pressure across different parts of the foot during movement. The arch, which experiences the least direct pressure, houses the electronics and battery.

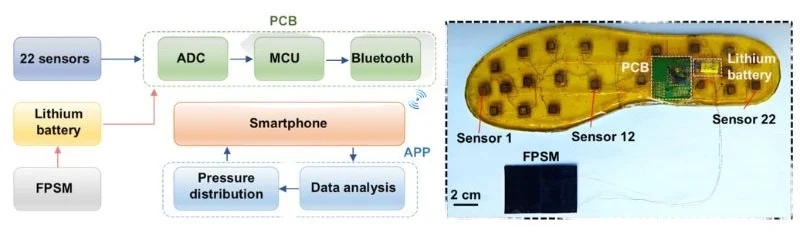

System architecture of the smart insole system.

On top of the shoe, two flexible perovskite solar modules (12 cm² each) harvest ambient light. These connect to a lithium battery mounted in the arch area, providing energy to run the sensors and electronics. Under full sampling conditions (32 Hz), the system draws 40.7 mW. Optimized operation modes—like lower sampling rates or Bluetooth Low Energy (BLE)-off mode—reduce power consumption as low as 0.33 mW. The system supports continuous function even in moderate indoor light, with fast solar recharging under high illumination.

A custom PCB collects data from the sensors and sends it to a smartphone via BLE. The mobile app includes three visual modes: real-time pressure display, a high-resolution pressure map (150 × 200 grid) using biharmonic spline interpolation, and continuous pressure vs. time graphs for individual sensors.

Gait Recognition and Data Precision

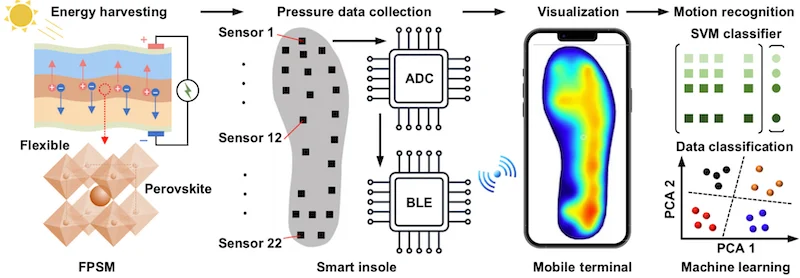

The system goes beyond passive pressure tracking. A built-in support vector machine (SVM) model classifies eight motion states: sitting, standing, single-leg standing, squatting, walking, running, ascending stairs, and descending stairs. The SVM achieved 100% recognition accuracy during testing, outperforming CNN-based models, which reached 99.55%.

The workflow of the smart insole system, from energy harvesting to pressure data collection and data classification using the SVM learning model.

The sensors capture pressure transitions and time durations that reveal clear differences between motion types. In walking, pressure shifts progressively from heel to toe, with contact lasting about half the step cycle. In running, the entire foot is under pressure nearly simultaneously, and contact time drops to around 25% of each stride. These patterns appear in dynamic pressure maps and can highlight abnormal movement or changes due to fatigue, injury, or disease.

The system records pressure events at a high temporal resolution and distinguishes subtle changes in how pressure moves through the foot. For example, differences in gait caused by conditions like Parkinson’s disease or diabetic neuropathy often show up as altered timing, asymmetry, or abnormal weight distribution, all of which the insole can detect.

Applications in Clinical and Preventive Settings

The smart insole has applications in clinical, preventive, and performance-based settings. It can track early signs of plantar fasciitis, detect gait changes linked to neurological conditions, and flag uneven load distribution that could cause foot ulcers in diabetic patients. For clinicians, it provides continuous, objective data that can supplement traditional assessments and support earlier interventions.

For rehabilitation, the system can monitor gait recovery in stroke patients or post-surgical recovery after knee or hip replacements. Physical therapists can use the data to track improvement in gait symmetry, weight-bearing behavior, or walking confidence. These metrics are difficult to measure accurately without equipment.

Threshed out structure of the insole, including CNT/ACET/PDMS sensors and PSCs.

In athletics, the insole can help prevent overuse injuries by identifying fatigue-related gait changes or poor load mechanics. It could also help optimize form in running or strength training by tracking foot mechanics under different training loads. For posture correction, the device’s real-time feedback allows users to address imbalances or habits before they lead to chronic issues.

The visualization tools make the data actionable without requiring lab equipment. Pressure distribution can be displayed in real-time color-coded maps, and more subtle deviations in center-of-pressure shifts or foot stance patterns can be reviewed over time to monitor progression or deterioration.

What’s Next for the Insole?

The prototype has already passed key durability benchmarks: 180,000 cycles of compression testing with no loss in accuracy or stability. The solar modules maintain over 96% of their output after 800 bending cycles and continue to function under normal wear-and-tear stresses. The sensing materials and insole structure are resistant to environmental wear, including humidity.

The team plans to improve gesture recognition and expand the range of detectable motions. They are also beginning testing across a broader set of users to ensure the algorithms perform well regardless of foot size, gait style, or body weight.

In the future, the team intends to integrate additional sensor types (e.g., temperature, moisture), expand interoperability with other wearables or IoT health platforms, and package the system for commercial-scale production. Researchers expect the insole to be commercially viable in three to five years.

The modular design allows for expansion into specialized use cases, such as workplace ergonomics, smart prosthetics, and athlete feedback systems, without redesigning the sensor architecture.

English

English