As demand for electric and autonomous vehicles increases, manufacturers face significant challenges in managing hundreds of individual connections. These connectors must deliver safe, reliable power and data transmission across complex vehicle networks. As a result, efficient and standardized connectivity solutions are essential to simplify vehicle assembly, reduce manufacturing costs, and enhance overall performance.

To address these needs, Tesla aims to consolidate and simplify vehicle electrical systems by introducing a standard connector tailored for modern electric vehicle architectures.

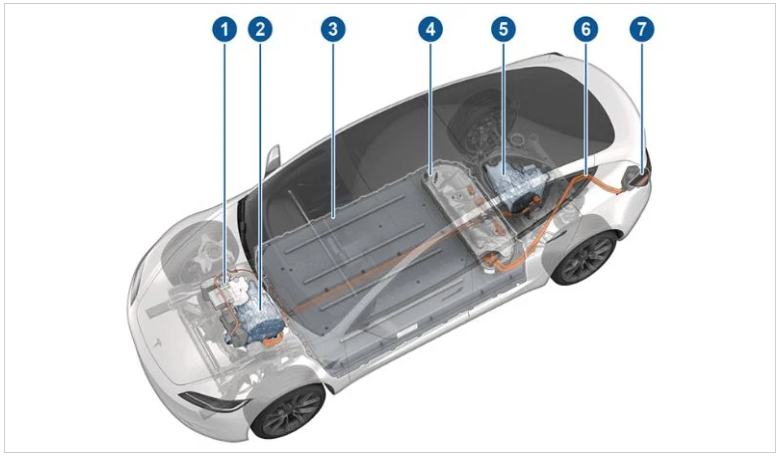

Tesla Model Y. Image used courtesy of Tesla

What’s Inside an EV?

As EVs have grown more technologically complex, the number of electronic components and connections has surged. A modern vehicle now typically requires over 200 connections, and each connector must reliably handle both power and signal transmission under varying conditions. This complexity increases manufacturing costs and assembly challenges, as connectors must meet distinct standards and specifications based on factors such as voltage, environmental exposure, and durability.

Tesla Model 3 electrical components. 1. Heat pump 2. Front motor 3. High voltage battery 4. High voltage components 5. Rear motor 6. High voltage lines 7. Charge port. Image used courtesy of Tesla

Another major challenge EV connectors face is the operation within the low-voltage architecture increasingly favored in automotive design, particularly the 48 V system architecture . The 48 V system is more efficient than the conventional 12 V system since, according to Ohm’s Law , with a fixed resistance, raising the voltage reduces the current. Lower current allows smaller, lighter wires to transmit the same power, saving weight and cost and improving efficiency.

High current also leads to greater energy loss and heat generation. Thus, a 12-volt system is inefficient at higher power levels and requires larger heat sinks than higher-voltage systems.

Tesla’s Automotive Connectivity Standard

Tesla has introduced its Low-Voltage Connector Standard (LVCS), a connector architecture designed to enhance the efficiency and scalability of EV systems.

LVCS is based on a 48 V electronic framework, which can deliver the same power as traditional systems but with a quarter of the current, reducing energy loss and allowing for lighter, more compact wiring. This architecture debuted in vehicles like the Cybertruck and includes specialized connectors that meet strict power and signal requirements with just six standardized types, covering over 90% of typical automotive applications.

The six connectors in the LVCS standard. Image used courtesy of Tesla

Each connector in the LVCS lineup features single-wire sealing and independent secondary locking mechanisms, which ensure durability under variable conditions while minimizing risks of disconnection or environmental contamination. The connectors are compact and maintain the required spacing for safe 48 V operation, with standardized configurations that support both autonomous functions and high-efficiency power distribution.

For ease of identification and assembly, the LVCS is color-coded in a standard light blue. Meanwhile, by consolidating numerous connector types into a smaller, uniform set, this design hopes to reduce manufacturing complexity, cost, and weight associated with traditional connector systems.

A Future Standard?

Following successfully standardizing its charging connector ( North American Charging Standard ), Tesla hopes to extend this approach to all other internal electrical connectors in its vehicles. Given Tesla’s leadership position in the industry, LVCS could set a benchmark for in-vehicle connectivity and eventually become a de facto standard for the entire industry.

English

English