Humans are tactile creatures. We use our sense of touch to judge everything from balance to the amount of pressure we must use to avoid breaking an eggshell. Yet many electronics we interact with often lack tactile feedback. Haptic motor company Titan Haptics is on a mission to help product developers easily integrate tactile feedback into their products.

Titan Haptics adds realistic recoil to StrikerVR’s Arena Infinity Blaster.

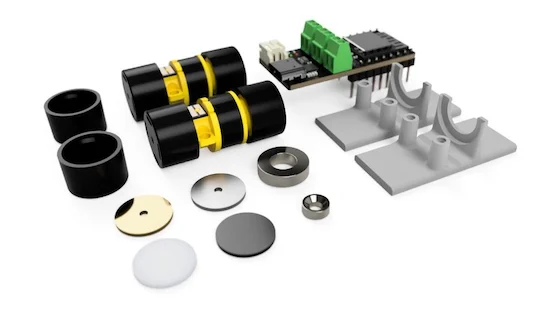

Now, the company is back with its newly released TacHammer Carlton haptics development kit , which includes all of the components necessary to explore, evaluate, and design physical feedback into games, controls, and other human interface devices. The new development kit is anchored on the TacHammer Carlton actuator. The kit comes with a pair of TacHammer Carlton haptic actuators, drive electronics, impact disks, and spare caps and magnets to enable customization.

The TacHammer Carlton Actuator

Titan Haptics' Carlton actuator is a double-ended 14 mm x 34 mm linear magnetic ram (LMR) motor that adds high-fidelity impact sensation to common tactile actions. The underlying technology to Titan’s LMR is a wideband voice-coil haptic motor. The motor uses solid-state magnetic suspension rather than springs or flexible attachments. It can mimic a hammer-type action with both a tactile feel and a metallic striking sound for even greater realism.

TacHammer Carlton actuator inside view.

The sliding magnetic slug can be slammed against an impact disk to create both a sound and a harsh simulated impact shock. Selectable impact surfaces allow developers to create experiences that better match the specific simulated experience. Plastic impact caps will produce a dull sound and softer sensation, while metal impact disks will deliver a metal-on-metal experience.

The actuator features three operating modes, including:

- Sharp: snaps, jolts, clicks

- Soft: pulses, taps, bumps

- Vibration: light wobble to intense vibrations

These modes are supported by 5 grams of steady-state acceleration (vibration), 25-G impulse acceleration, and a 10–300-Hz frequency response. The Carlton is a two-sided device enabling customizable impact pieces to be doubled up or mixed. This flexibility gives even greater flexibility to developers.

Development Board Features

The development board included in the kit features an ESP32 processor with integrated Wi-Fi and Bluetooth. The board directly drives up to three actuators with three haptic channels, including screw-in headers. It comes with USB and power circuitry that can be broken off when the board is integrated into a production system. It also includes a dual-channel, class-D audio amplifier to deliver sound in concert with the haptics feedback.

New TacHammer Carlton development kit contents.

The board includes up to 13 GPIO and supports I2C, I2S, and SPI—all in a 44.8 mm x 20.8 mm x 18.6 mm form factor.

Developer Support

In addition to the mechanical and electronic hardware, Titan Haptics has a complete software development kit available. The SDK comes with an open API (Vector Haptics) and cross-platform compatibility. The ESP32 driving the development kit’s control board is a widely used 32-bit processor designed around wireless connectivity. The ESP32 ecosystem and development community covers a broad set of applications from DIY and hobby to commercial product design and development.

Haptics in the Real World

Most machine-to-human communications come in visual or audible formats. Haptics adds the ability to communicate kinesthetically with physical motion. Haptics originated in the aircraft industry in the 1940s and 50s with systems that would tell pilots of large aircraft that they were about to enter an aerodynamic stall. Early haptics in the electronics world included force feedback joysticks in the 1990s and commercial video game controls even earlier. However, the cost and complexity of these systems have had limited widespread use until the last decade.

Today, haptics are used in gaming, simulation, and “by wire” controls that need to give realistic simulated mechanical feedback. Common applications include simulated road feedback in electric automotive power steering, game controls that simulate gunfire or physical combat, and smartphone touchscreens that mimic physical button presses.

Titan Haptics claims its TacHammer Carlton development kit includes everything a designer might need to prototype and fine-tune impact-based haptics. As one of the only actuators with mechanical tuning options built-in, the TacHammer Carlton dev kit allows developers to change the physical feel and sound of tactile feedback without modifying firmware or software.

English

English