Today, startup Eyeo has announced a breakthrough optical waveguide technology that eliminates light-blocking filters on digital image sensors. The company has closed €15 million ($17 million USD) in seed funding to build development kits, expand partnerships, and scale manufacturing for a first commercial product.

Eyeo's image sensors collect light without filtering, drastically improving image quality.

Eyeo Solves the Camera Filtration Problem

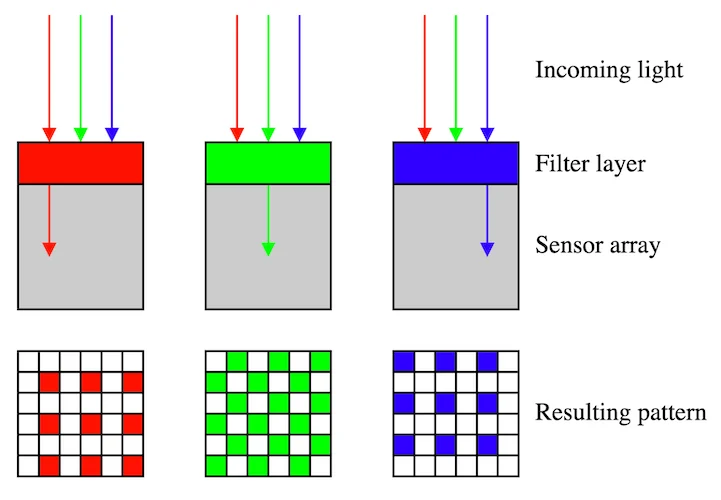

Today’s digital cameras use filters to split light into primary colors by area. Each pixel is made up of three sub-pixels, each of which has a primary color filter over it. This means that each pixel inherently loses up to 2/3 of the light coming in. This filtration reduces the incoming light intensity by 70%.

"This technology, it's really disrupting an industry that has since forever used these color filters that have been throwing away 70% of the light," says Hoet. "Now, with this technology, we can actually use all of it."

Conventional color image sensor structure.

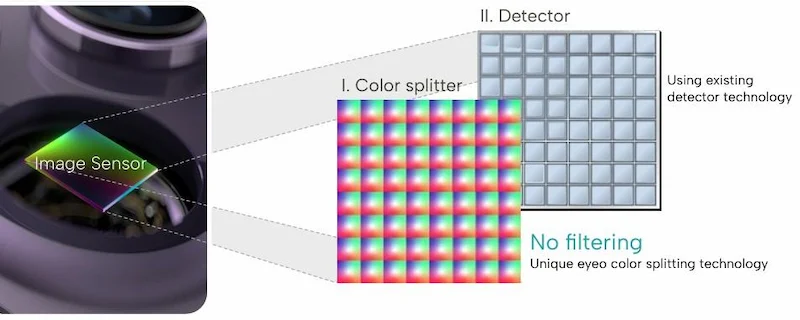

The Eyeo sensor uses a technology developed by Imec, a Belgium-based nanoelectronics and digital technology research and innovation hub. The new technology, called wafer-level-integrated vertical-waveguide sub-diffraction-limited color splitters, uses vertical optical waveguides to transport all photons to designated primary color pixels.

The complete spectrum is collected from each pixel area and directed via waveguide to the appropriate sub-pixel.

Incoming light is routed rather than being selectively blocked, delivering greater light intensity to each pixel. The filter-less sensors will allow three times the light gathering capability for a sensor of the same size, or a sensor one-third the size with the same performance. What’s more, the waveguide will work with existing CMOS image sensor technology. It can be built with conventional fab equipment on top of a CMOS image sensor.

“What we are doing is we have a technology that allows us to collect a lot more light than what is possible with current technologies,” says Hoet.

“It's as if you are opening the eyes of an image sensor, so it’s eye-opening, That’s the background of our company name: Eyeo.”

An Optical Waveguide Breakthrough?

Digital image sensors are at a crossroads. They need higher pixel counts to deliver true-to-life picture resolution and larger pixel apertures to deliver noise-free, low-light performance. These two factors work against each other. Color capture adds to the problem by reducing both pixel size and light gathering capability.

A color “pixel” is made up of three smaller pixels, each with a red, green, or blue filter. The filters block up to 2/3 of the available light that is outside their spectrum. Further, the primary filters also block some of the color intended for each same-color subpixel. The need for three filters also puts physical limitations on pixel size. Currently, the industry is stalled at 0.5-micron pixel sizes. Below this size, the structure becomes too large a factor, and optical diffraction limitations impact sensor capability.

Eyeo's optical waveguides take all photons from a given pixel area and guide them based on wavelength to one of three sub-pixels. This allows the CMOS sensor structure and electronics to remain virtually unchanged.

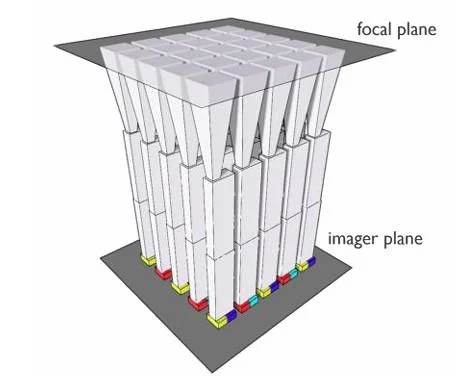

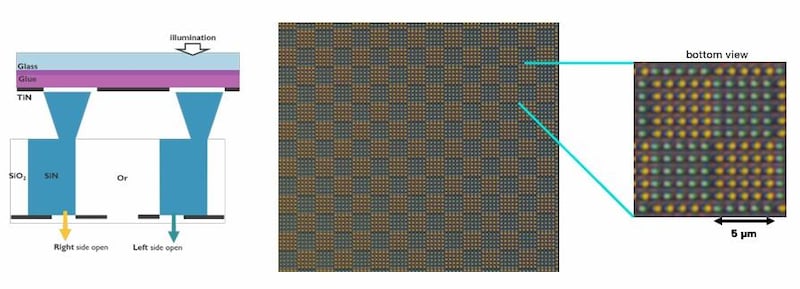

BY-CR imaging waveguide stack.

The system uses stacked vertical waveguides to capture full-spectrum white light and then guide each component, based on wavelength, to a different pixel. The scientific paper covering the waveguides illustrates blue/yellow and cyan/red splitting waveguides.

Side view layout of waveguides and resulting patterns on the image sensor.

The guides are tuned to direct light based on the average sensitivity of human eye color sensing cones. The waveguides can be tuned to different light wavelengths for specialized applications such as UV or custom spectral ranges. The scientists who developed the technology found that “the total output light from each waveguide is more than 90% in the wavelength range 400–700 nm, which is far superior to color filters.”

A Clear Vision of Small, High-Performance Sensors

Eyeo has demonstrated the technology and partnered with major image sensor foundries. Its next step is to use the seed funding to move closer to delivering a manufacturable product. The ultimate aim is to deliver image sensors with greater light sensitivity and sub-0.5 micron pixel size for improved performance and smaller size. The ability to reduce sensor size and maintain high image quality will enable smaller devices and true-color imaging for a wide variety of consumer and commercial products.

English

English